Metabolizing Heat: Thermally Tuned 3D-printed Envelopes

Although still at a nascent stage for building construction, Multi-Material Additive Manufacturing (MMAM) has emerged as a promising technology for the industry to overcome this limitation and reduce the embodied carbon of 3D printed structures by limiting the use of structural materials through topology optimization strategies.

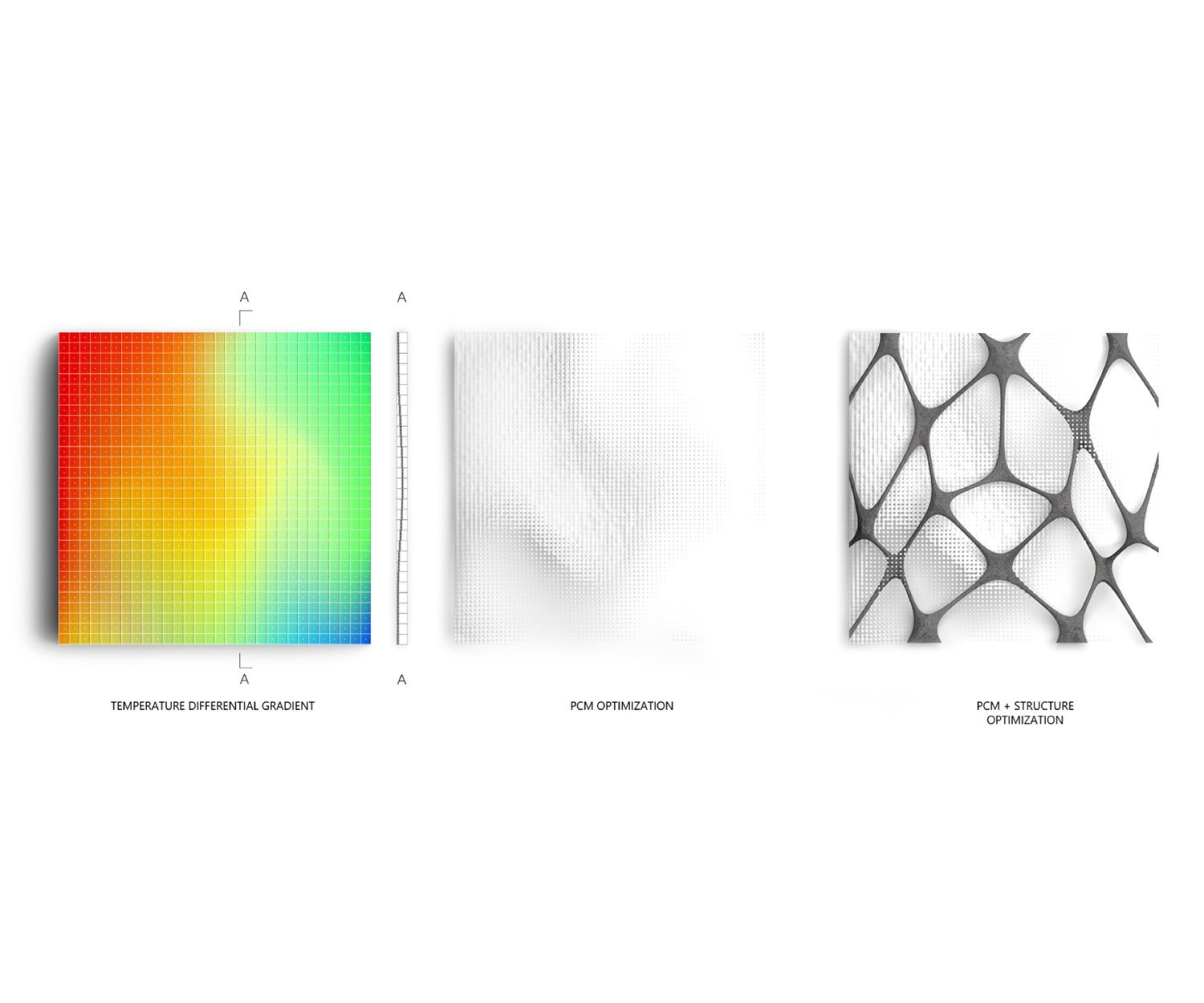

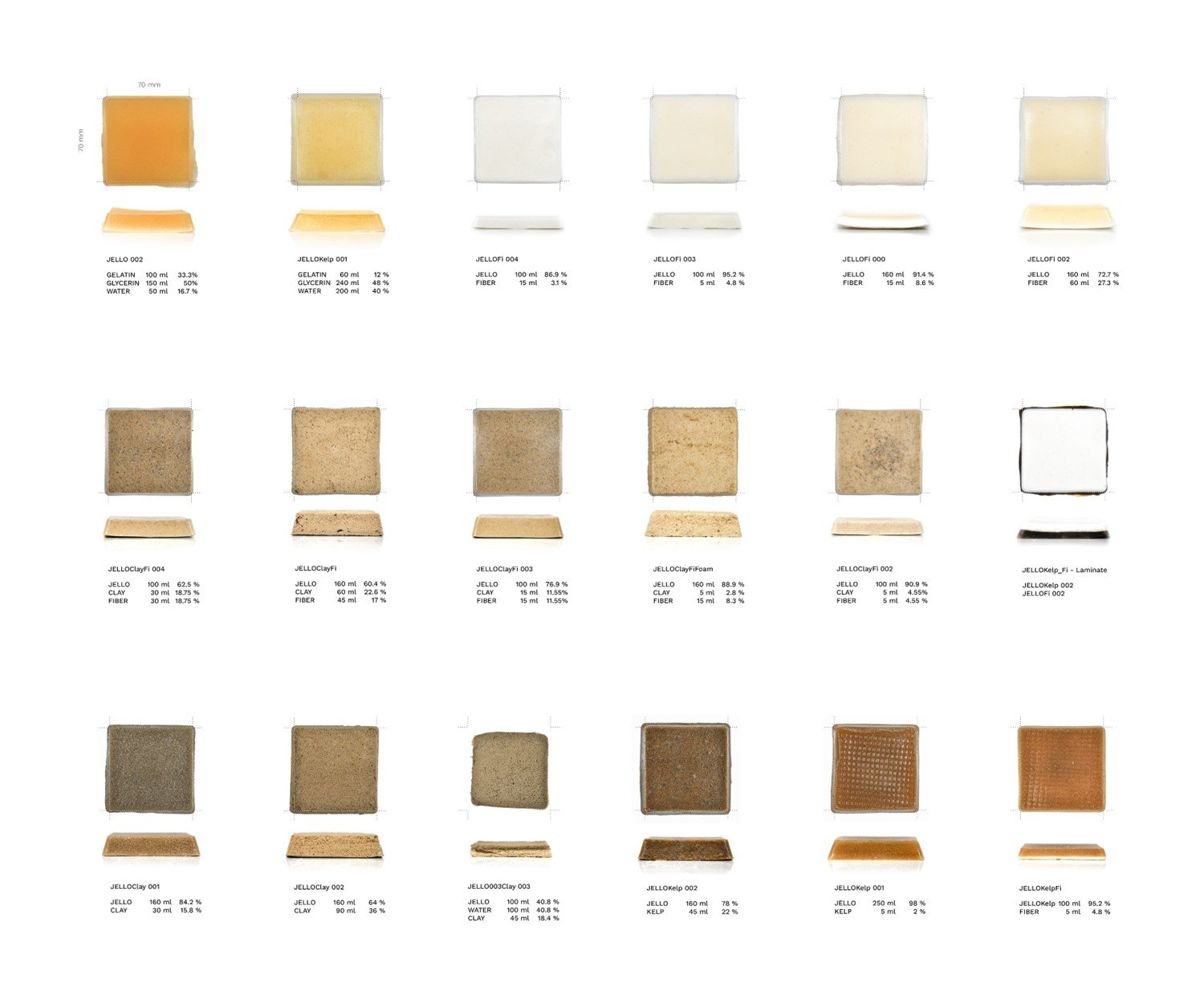

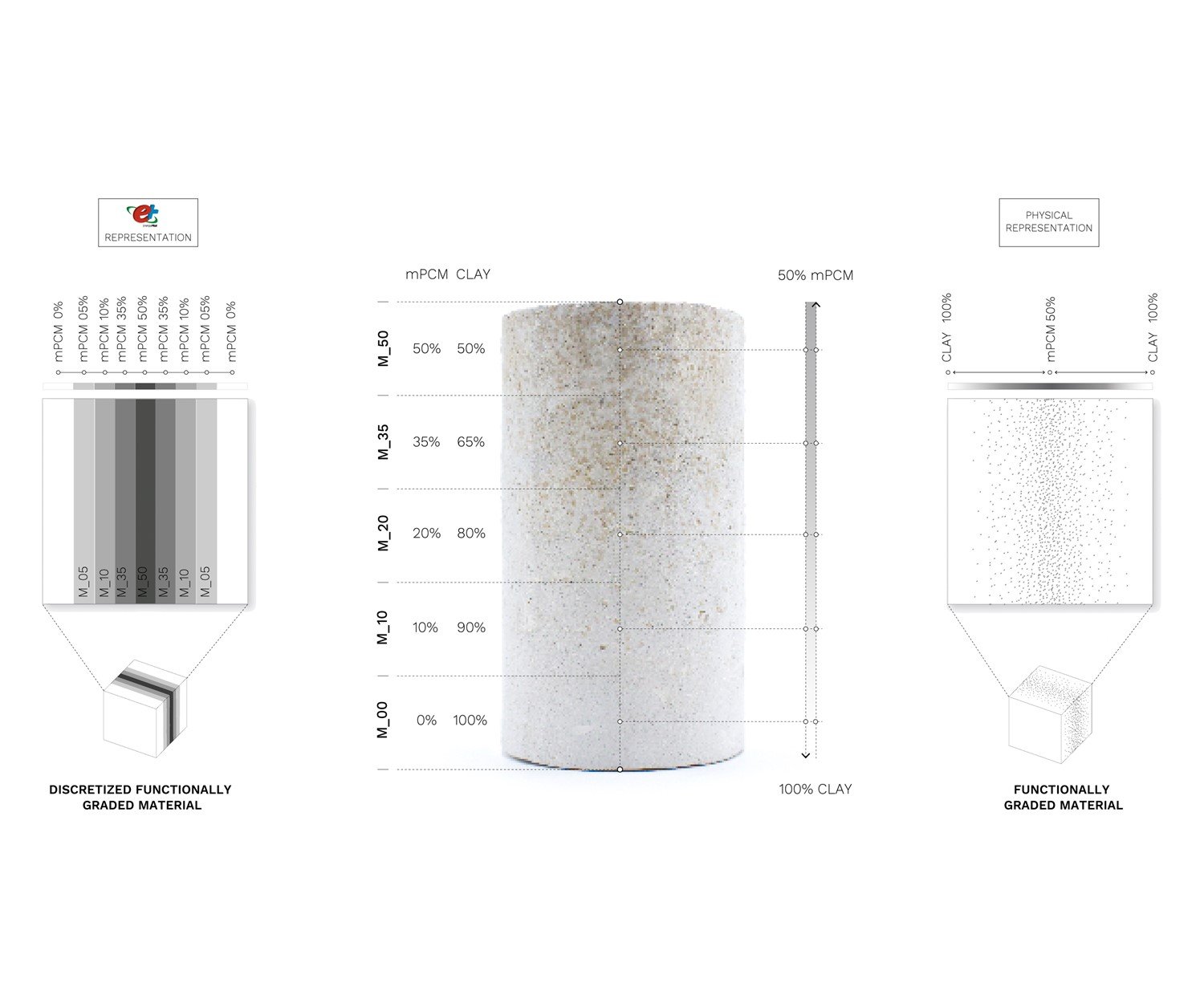

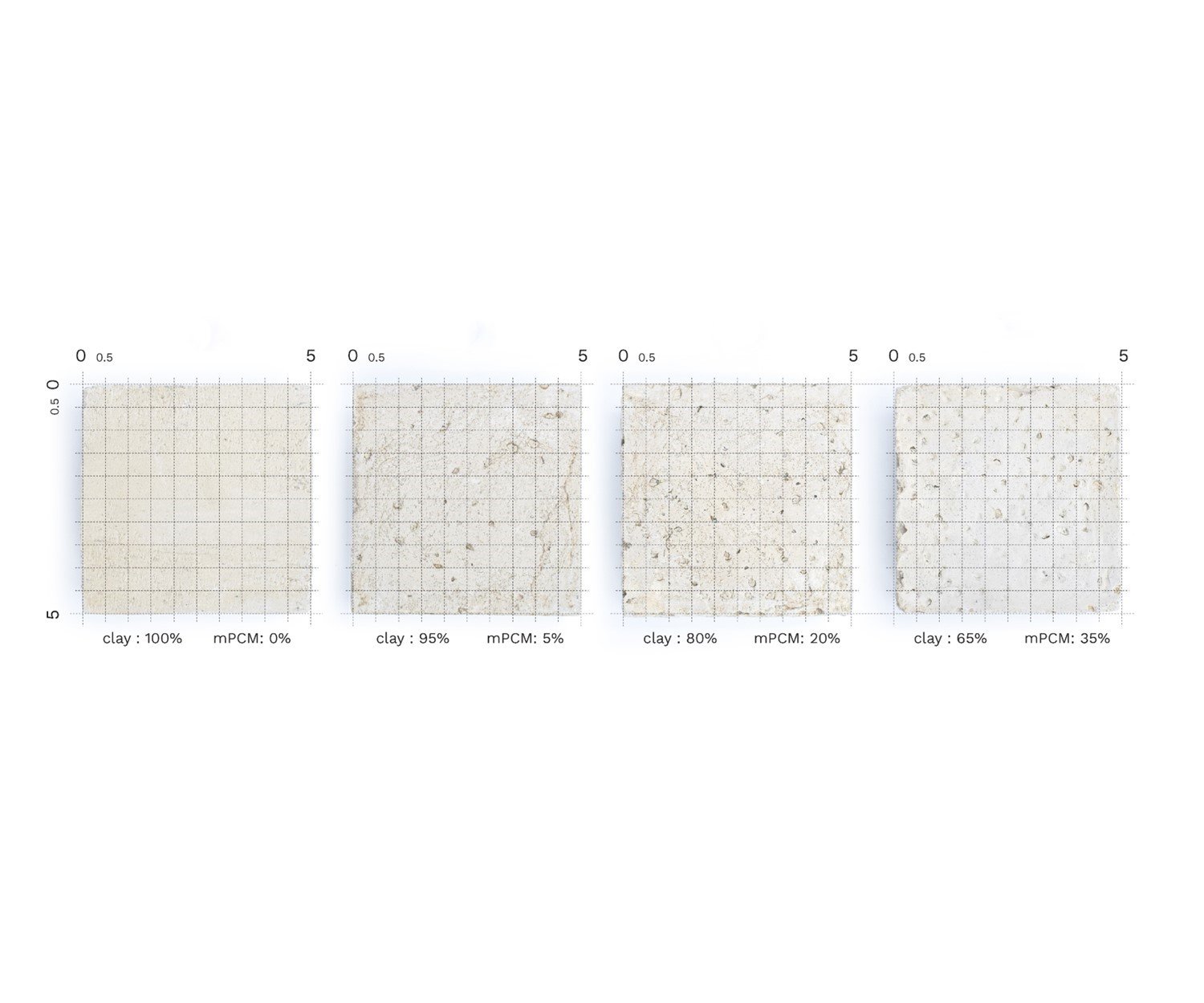

MMAM enables the fabrication of functionally graded materials (FGMs) by controlling the extrusion ratio between two or more distinct materials, resulting in building envelopes with multiple performance characteristics and functions. While research has focused on improving the structural performance of 3D-printed envelopes through MMAM, limited attention has been given to optimizing thermal performance and energy efficiency.

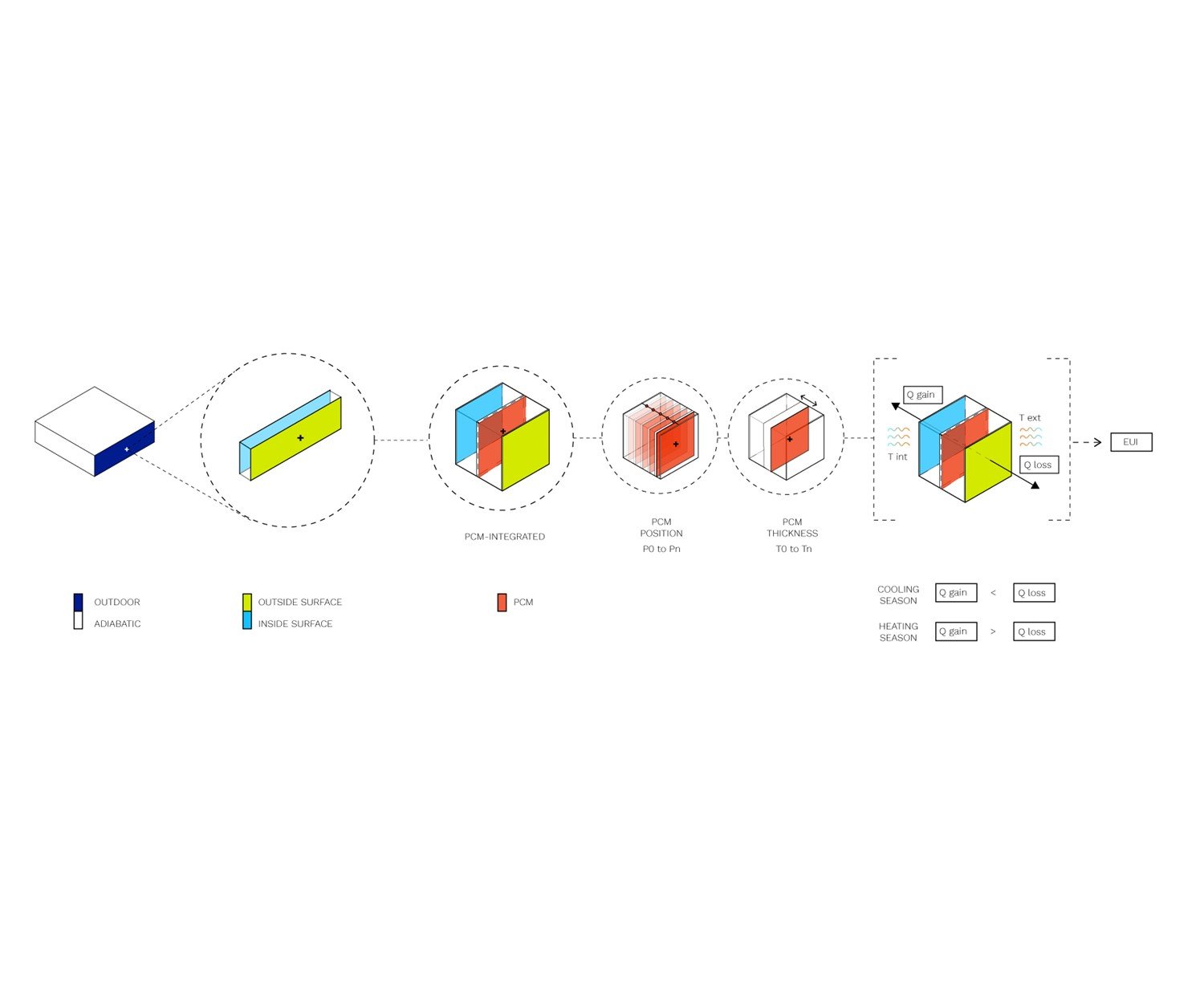

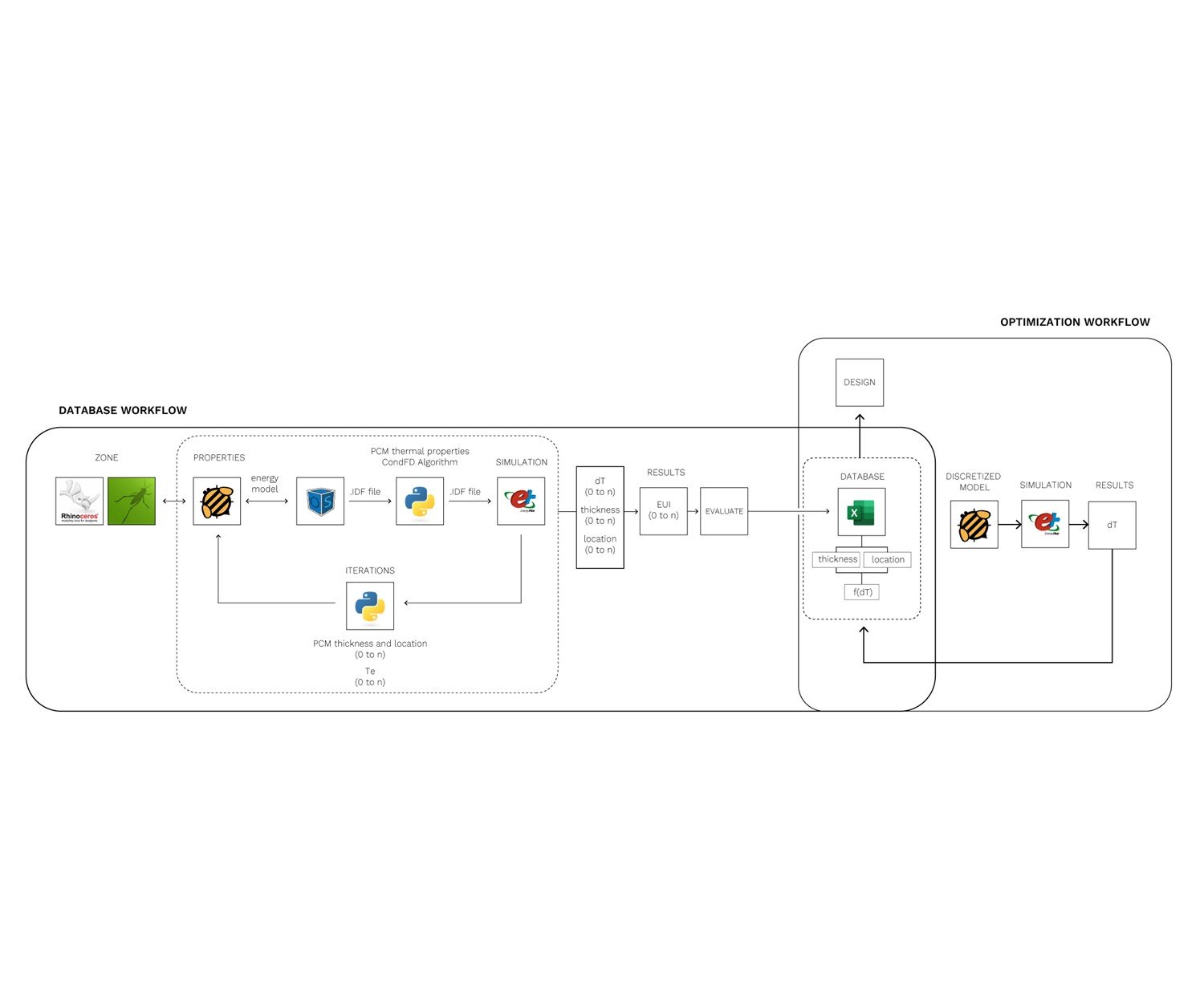

To this end, this project aims to develop strategies to improve the energy efficiency of 3D printed buildings by locally tuning heterogenous material properties and optimizing their distribution during the additive manufacturing process through the use of thermal energy storage (TES) materials such as phase change materials (PCMs) characterized by high latent heat storage capacity.

Project Date: 2022-present

Researchers: Elena Petruzzi and Alexandros Tsamis

Collaborator: Chaitanya Ullal